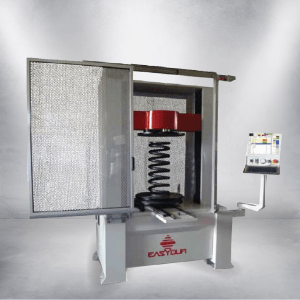

Manufactured by: FAMAK and PARIZAN SANAT (Poland and Iran)

Wagon tipplers are used for the unloading of loose bulk materials from open-top railway wagons.

There are two basic types of tipplers based on the unloading methods, rotary tipplers and side tipplers.

A railway wagon is unloaded by its turning together with the tipplers’ rotary part around the axis parallel to the axis of the runway so that the contents of the wagon fall gravitation ally to a storage bin located under the tippler.

A side tippler additionally lifts a wagon during the unloading operation, thus considerably reducing the necessary depth of a slotted storage bin.

Possible solutions for the holding of wagons on tipplers during the unloading operation:

- line tipplers,

- Hydraulic tipplers

- Mechanical tipplers.

A wagon tippler consists of the following main units:

- Supports with wheels

- A rotary structure with end rings

- A rotation drive

- A wagon clamp device.

Famak Wagon Tippler Features

- control systems based on programmable logic controllers

- electronic speed control systems

- positioning of a machine’s all mechanisms

- auto diagnostics and closed-circuit TV

- automatic central lubrication systems

- online maintenance operations.